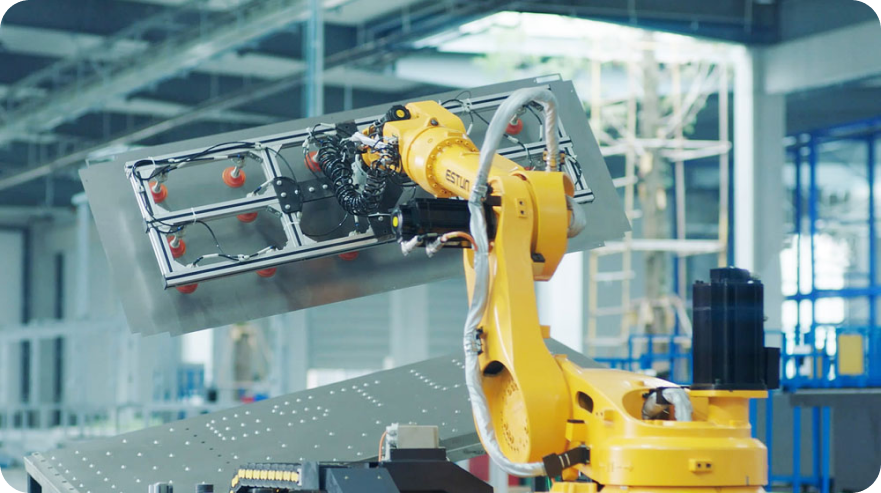

Strategically located in Monterrey, Mexico, the Sunon Mexico Manufacturing Base and Experience Center establishes Sunon as the only Chinese office furniture brand with a manufacturing presence in North America.

Covering more than 816K square meters (approximately 8.78 million square feet), this cutting-edge facility integrates production, supply chain operations, and quality control to provide high-performance office solutions tailored to the U.S., Canadian, and Mexican markets. With an annual production capacity exceeding 1 million chairs and 500K workstations, we ensure efficient and timely delivery to support our clients’ needs.

This facility reflects Sunon’s unwavering commitment to innovation, sustainability, and customer-centric service, delivering world-class quality closer to our North American customers.

Desks + Workstations

Desks + Workstations StoragePanel + Space Division

StoragePanel + Space Division Accessories

Accessories Desks + Workstations

Desks + Workstations StoragePanel + Space Division

StoragePanel + Space Division Accessories

Accessories